Why Auxiliary Power?

Why Auxiliary Power?

Most long-haul truck drivers spend 250-300 days and nights on the road every year, and sometimes more. That means living in your truck for 68–82% of the year. In that time your truck becomes your home—the place where you eat, sleep, work and wind down. To make this manageable, you deserve basic home comforts like an HVAC system, kitchen appliances, TV and home electronics. But if you run these systems off the main engine, you’ll dramatically increase your fuel consumption and emissions. When your truck is stationary, you’ll also run into the issue of excessive idling. You can find out more about idling issues, regulations and idle reduction here. So, what are the alternatives to excessive idling?

What is Auxiliary Power?

Auxiliary power is used to fuel parts of your truck that aren’t attached to your main engine and systems. One of the most common forms of auxiliary power is an electric APU (auxiliary power unit). Traditional APUs run on small diesel generators, creating energy from much smaller motors than your engine, so using less fuel. However, these are heavy, noisy and with growing emissions control regulations, are slowly becoming less practical.

Electric APUs run on batteries and charge off your engine, alongside your starter batteries. These auxiliary batteries are also called a house battery bank. They are connected up by an inverter, which lets your starter and house battery bank charge together while your engine is running, but separates them when it’s off. This way, your appliances run off the house battery bank and not the starter battery. It’s best to avoid regularly running appliances off the starter, as this can drain and even damage the battery. By powering your amenities when your engine’s off, the electric APU also functions as an idle reduction system. This cuts fuel costs, preserves your engine and aftertreatment system, and avoids the hefty fines associated with idling.

What is the Difference Between the Starter Battery and the House Battery?

Most commercial trucks with an electric APU installed have two sets of batteries. The starter battery retains the power to start the engine. Your house battery bank is the power plant for your electric APU, which powers long-haul essentials like your TV, fridge and microwave to let you get the most out of your sleeper cab. While lead-acid batteries work very well for starter batteries, there are a number of drawbacks to using them to fuel your house battery bank. You can find out more about the differences here.

Diesel Generators and Lead Acid Batteries

The eAPU, or electric APU, runs off an auxiliary/ house power bank. The auxiliary batteries are separate from your starter battery but charge in the same way, using extra power generated by the truck’s engine. However, there are drawbacks to using an electric APU. While they work perfectly well to power an HVAC system, they often lack the capacity to power your amenities as well. This can cause issues like restricted run times, limited depth of discharge and the need for regular re-charging.

Why Lithium Batteries?

If your electric APU only runs for four hours between charges, this can be inconvenient and disruptive, especially at night. You may find yourself getting up every few hours to turn on your engine and charge your batteries. In the process, you’re unwillingly driving up fuel costs and risking large fines if you’re caught idling for longer than permitted. This can seem like a catch-22, but there is a solution! Many of these problems stem from the fact that it’s common practice to use inefficient lead-acid batteries to power your APU.

We designed deep-cycle LightningVolt™ lithium batteries as an upgrade to traditional batteries. Lithium batteries run twice as long between charges as their AGM counterparts, lasting up to 10 hours, and offer greater depth of discharge. This doubles the usable power and means fewer and shorter engine starts. This enables you to drive down your idle time and fuel costs, while still running your electronics for long periods. As an added bonus, LightningVolt™ batteries have 10× the lifespan of traditional ones. This means that investing in 1 LightningVolt™ battery saves you from replacing 10 AGM batteries!

So why choose LightningVolt™?

As trucking equipment specialists, the Roadwarrior team built our heavy-duty battery to meet standard road conditions like vibration and shocks. Based in Canada, we are uniquely placed to understand how diverse terrain, steep gradients, and mixed weather conditions affect North American long-haul truckers.

Our LightningVolt™ design factors in the kind of variables that raise fuel costs through increased heating, air-con and electricity requirements. You can start our deep-cycle battery without running your engine and it withstands extreme temperatures, from heat waves to cold snaps. This keeps down fuel costs and gives you peace of mind in the more extreme months.

LightningVolt™ comes in a standard Grp 31 size, making it a perfect fit for electric APUs that were running on lead-acid or AGM batteries. As an added bonus, they weigh half as much as traditional lead-acid batteries, providing long-term weight reduction. This is especially valuable in states that run eAPU incentive programmes, offering 400lb, or in some places 550lb weight exemptions to trucks that adopt this anti-idle technology. Many state governments also offer rebates, tax exemptions and incentive schemes for truckers and owner-operators considering idle-reduction technologies like electric APUs.

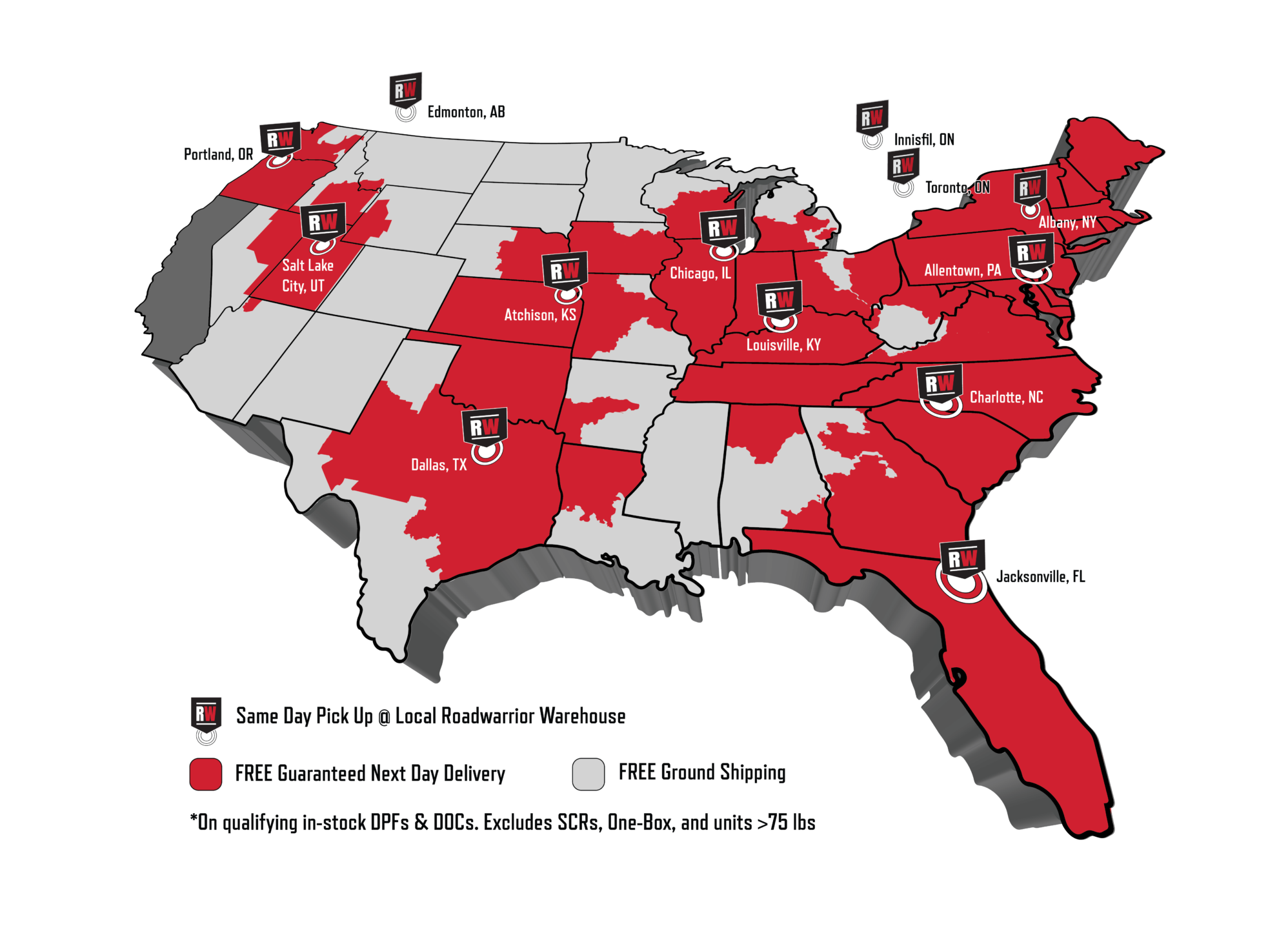

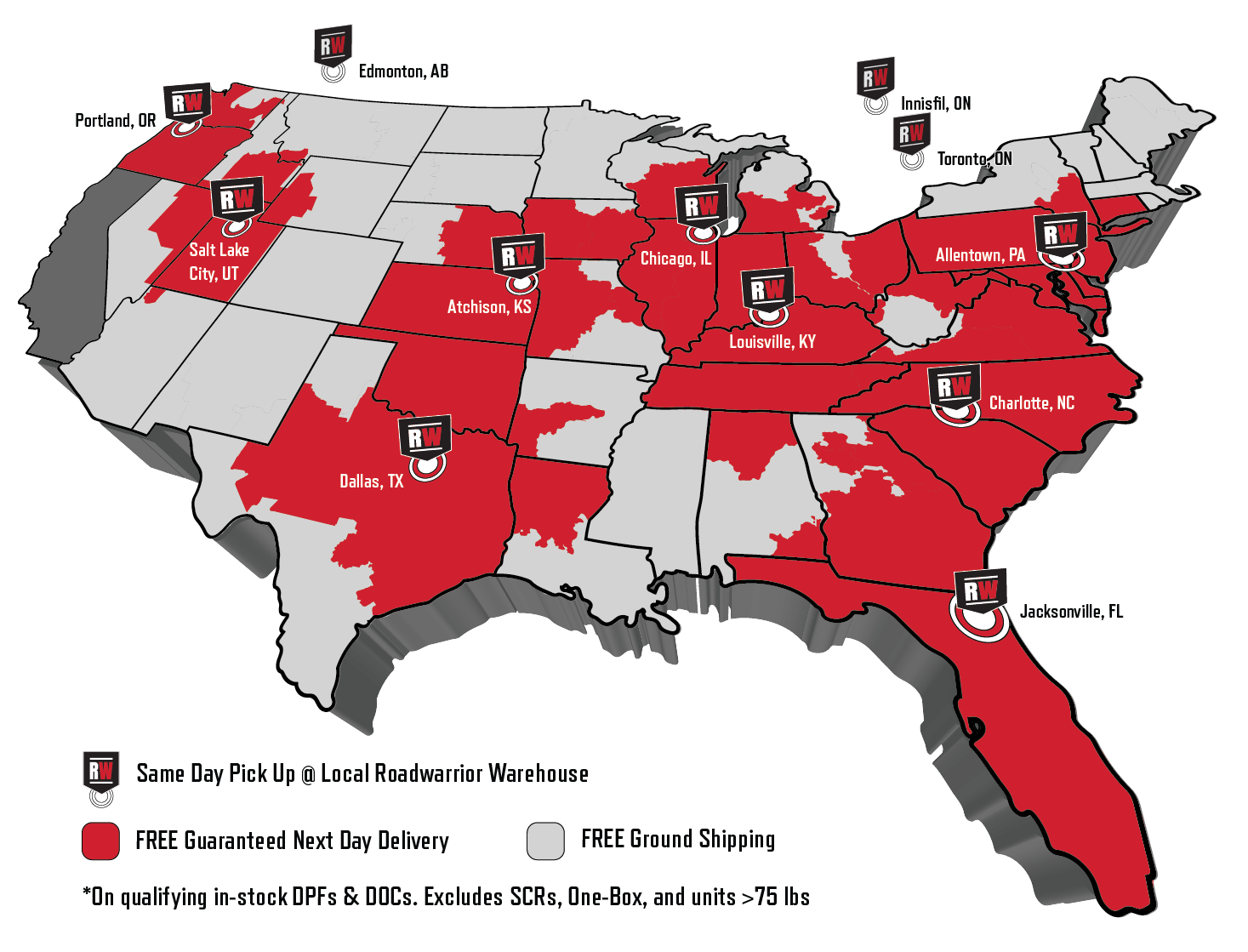

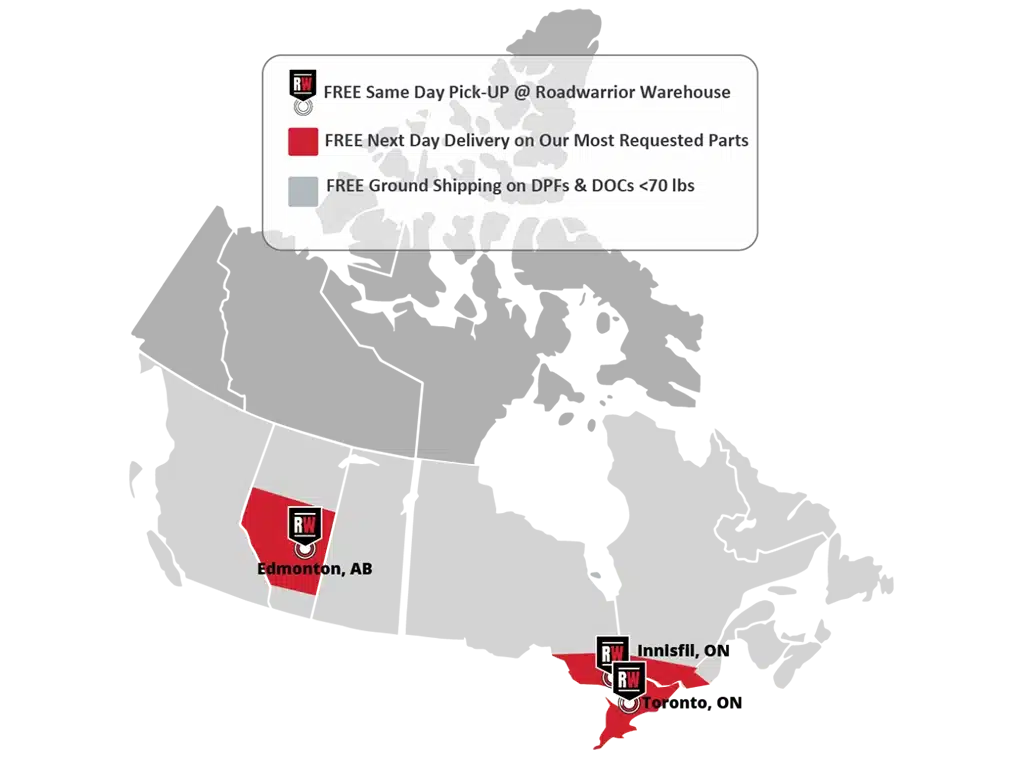

Why Did Roadwarrior Start Developing Batteries?

Here at Roadwarrior, we specialize in meeting the needs of the trucking community. We provide an aftermarket option for hard-to-replace aftertreatment parts like DPFs, DOCs and SCR. We developed our LightningVolt™ lithium batteries when we noticed the extra wear and tear the engine and aftertreatment components receive from extended engine idling. By installing lithium batteries as an idle reduction system, long-haul truckers can cut fuel costs, and idle times, and extend the life of their engine and related systems. Our catalogue also extends to smaller parts like NOx sensors, clamps and DEF dosers.